Nobel Chemistry 2025: Kitagawa, Robson and Yaghi Honored for Metal‑Organic Frameworks

Oct, 9 2025

Oct, 9 2025

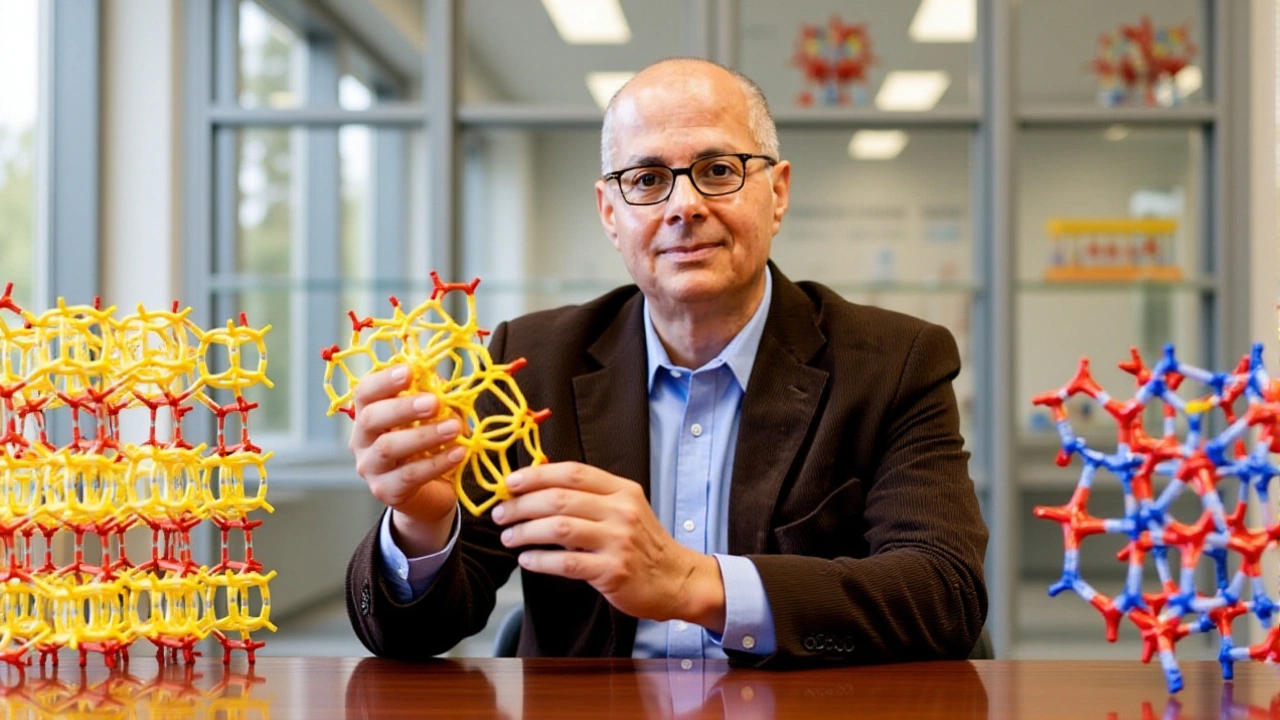

When Susumu Kitagawa, professor at Kyoto University joined Richard Robson, research professor at University of Melbourne and Omar M. Yaghi, James and Neeltje Tretter Chair Professor of Chemistry at University of California, Berkeley received the Nobel Prize in Chemistry 2025 from the Royal Swedish Academy of Sciences in Stockholm, they were honored for pioneering metal‑organic frameworks (MOFs), a class of porous crystals reshaping energy, water and medicine.

Background: How MOFs Became a Scientific Breakthrough

Metal‑organic frameworks trace their roots to the early 1990s. In 1990, Richard Robson published the first examples of infinite coordination polymers, effectively laying the conceptual groundwork. A few years later, Susumu Kitagawa demonstrated permanent porosity in what he called porous coordination polymers, proving that these materials could trap gases. Meanwhile, Omar M. Yaghi introduced the idea of reticular chemistry in 1995, a systematic way to stitch metal nodes and organic linkers into predictable, crystalline lattices.

The trio’s work converged into what the Nobel Committee described as “a new type of molecular architecture.” By 2025, researchers worldwide had designed more than 100,000 distinct MOF structures, each fine‑tuned for a specific molecular guest.

The 2025 Nobel Announcement

On 8 October 2025, at 11:53 AM UTC, the Royal Swedish Academy of Sciences gathered in its historic Stockholm headquarters. Hans Ellegren, the academy’s secretary‑general, read the citation: “for the development of metal‑organic frameworks.” Each laureate will receive one‑third of the 11 million Swedish kronor prize—roughly US $1.2 million.

Yaghi’s reaction unfolded at Brussels Airport, where he was en route to a conference. According to a UC Berkeley news release, he stared at a silent phone, then got the call that changed everything. “There is nothing like this, it’s an astonishment,” he later told reporters, while juggling congratulatory messages and a scheduled talk the next day.

How MOFs Work and Their Real‑World Applications

At their core, MOFs combine metal ions or clusters (often zinc, copper or iron) with organic linkers such as carboxylates. The resulting crystal looks like a three‑dimensional scaffold peppered with uniformly sized pores—think of a designer apartment building where each room is tuned for a particular guest molecule.

These engineered cavities enable a suite of impressive feats:

- Harvesting water from desert air: up to 0.7 L kg⁻¹ day⁻¹ at 20 % relative humidity.

- Removing per‑ and polyfluoroalkyl substances (PFAS) from polluted water with >99 % efficiency.

- Capturing CO₂ from flue gases at 3–5 mmol g⁻¹ adsorption capacity.

- Storing hydrogen at 10–15 wt % for fuel‑cell vehicles.

- Compressing methane for natural‑gas trucks at 2.8 × the density of conventional CNG.

- Extending fruit shelf life by trapping ethylene, boosting freshness by up to 300 %.

Beyond environmental tech, MOFs serve as carriers for pharmaceuticals, catalysts for chemical reactions, and even as scaffolds for enzyme immobilization that break down trace antibiotics in wastewater.

Industry Uptake: From Lab Bench to Factory Floor

Commercial production crossed the 100‑metric‑ton threshold in 2025. German chemical giant BASF SE in Ludwigshafen has been scaling MOF synthesis for gas‑purification modules used in semiconductor manufacturing. Across the Pacific, NuMat Technologies in Redwood City, California, focuses on high‑surface‑area MOFs for drug delivery, reporting pilot‑plant yields that meet pharmaceutical‑grade purity standards.

The surge reflects not only the materials’ versatility but also growing confidence in their long‑term stability—a concern that haunted early adopters. Today, MOFs survive harsh temperatures, radiation, and even acidic environments, making them viable for real‑world deployment.

Expert Perspectives and Future Outlook

Professor Jennifer A. Lewis, a materials scientist at Harvard University, notes that “MOFs have moved from curiosity to cornerstone of sustainable chemistry.” She points to ongoing research into MOF‑based solid‑state batteries, which could double energy density compared with current lithium‑ion cells.

Meanwhile, policymakers are eyeing MOFs as a tool for meeting climate goals. The European Commission’s recent draft legislation cites MOF‑enabled carbon capture as a “critical technology” for achieving the 2030 emissions reduction target.

Looking ahead, the next frontier may be “smart MOFs” that change pore size on demand, triggered by light or electric fields. If the past three decades have taught us anything, it’s that the imagination of chemists can turn a simple glass beaker experiment into a global solution.

Key Facts

- Prize: Nobel Prize in Chemistry 2025 (11 million SEK total).

- Laureates: Susumu Kitagawa (Kyoto University), Richard Robson (University of Melbourne), Omar M. Yaghi (UC Berkeley).

- Core achievement: Development of metal‑organic frameworks (MOFs).

- Commercial output: >100 metric tons of MOFs produced annually (2025).

- Major applications: water harvesting, PFAS removal, CO₂ capture, energy storage, food preservation.

Frequently Asked Questions

What exactly are metal‑organic frameworks?

MOFs are crystalline materials made from metal ions or clusters linked by organic molecules, creating a highly porous network. Their pores can be tuned to exact sizes, allowing selective adsorption of gases, liquids or even biomolecules.

Why did the Nobel Committee choose MOFs over other technologies?

The committee highlighted MOFs’ unprecedented versatility—one family of materials now underpins advances in clean water, carbon capture, energy storage and drug delivery, representing a unifying platform that bridges chemistry, engineering and environmental science.

How are MOFs being used to address water scarcity?

Certain MOFs can pull moisture from dry air, condensing up to 0.7 liters of water per kilogram of material each day. Pilot installations in arid regions of Australia and the Middle East have already demonstrated enough output to supply small communities.

Which companies are leading the commercial production of MOFs?

Germany’s BASF SE focuses on large‑scale MOFs for gas purification, while California‑based NuMat Technologies specializes in high‑purity MOFs for pharmaceuticals and battery research.

What’s next for MOF research after the Nobel win?

Researchers are pursuing “dynamic” MOFs that respond to external stimuli—changing pore size under light or voltage. Such smart materials could enable on‑demand gas release or adaptive drug delivery, expanding the technology’s reach even further.